XD16N Bar

XD16N is a high Nitrogen Martensitic Stainless Steel for corrosion, temperature, and wear resistance. This grade is an air-melt only, less costly version of XD15NW, yet still offers greatly superior corrosion resistance to 440C or 440C VAR.

| FOR REQUIREMENTS: | Stainless Bearing Steel, High-Nitrogen |

| MELT PRACTICE: | Air-Melt |

| CORROSION RESISTANCE: | Superior to 440C/EXCELLENT |

| ALTERNATIVE TO: | 440C/440C VAR or AMS 5749 |

| SPECIFICATIONS: | AMS5926 X50CrSiMnVN16-1 UNS : S42716 |

Benefits of XD16N

- Significantly better corrosion resistance relative to 440C (X105CrMo17)

- HRC of at least 58 after tempering at low (around 180°C) and high (500°C) temperatures

- Low residual austenite after heat treatment in order to ensure a high dimensional stability of the parts

- Capable of high temperature hardness, superior even to AMS 5749

- Heat treatment is relatively simple, utilizing standard equipment

- Cost effective alternative to XD15NW (non-flight critical applications)

Typical Applications

- Gears

- Valves

- Injection systems

- Cold work in corrosive environments

- Blades and cutting tools

Comparison to Other Materials

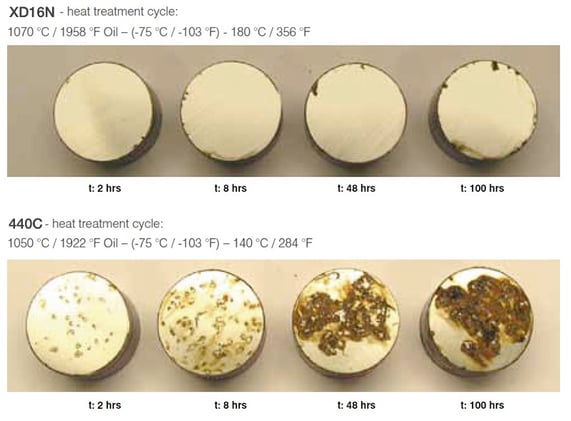

The corrosion resistance is characterized with the following test:

• Salt spray test according to NF X 41-002

As shown in the pictures below, the corrosion resistance is significantly better when compared to the standard solution X105CrMo17 (440C, remelted in this case). Surface aspect after different salt spray (NaCl) exposure times.

Chemical Composition

| C | Si | Mn | Cr | Mo | V | N | Ni | |

|---|---|---|---|---|---|---|---|---|

| min. | 0.45 | 1.30 | – | 15.00 | 0.20 | 0.20 | 0.05 | – |

| max. | 0.60 | 1.70 | 0.80 | 16.50 | 0.40 | 0.40 | 0.20 | 0.40 |

Stocking Sizes

| XD16N Bar & Wire Coil: | 0.217″ø to 5.50″ø (5.5 mm ø – 140 mm ø) |

| XD16N Flat Bar | 0.625″ wide x 6.000″ thick 1.250″ wide x 1.500″ thick |

Brochure & Datasheet