XD15NW® (X40CRMOVN16-2; AMS 5925)

XD15NW® is a high-nitrogen martensitic stainless steel primarily used for bearings and ball screws. This grade was developed for high stress applications where high hardness, fatigue resistance, and corrosion resistance are paramount, making XD15NW® the logical choice for any part requiring a stainless steel that cannot fail.

One of the most corrosion-resistant bearing-quality grades available in the U.S. today, XD15NW® meets the AMS 5925 spec, an alternative to AMS 5898. It is further categorized by the chemical classification X40CrMoVN16-2, UNS designation S42025, and DIN specification 1.4123.

XD15NW® is available as electro-slag remelted (ESR) bars from Sullivan Steel, the exclusive North American distributor of XD15NW®.

| FOR REQUIREMENTS: | Stainless Bearing Steel, High-Nitrogen (CREN) |

| MELT PRACTICE: | ESR |

| SPECIFICATIONS: | AMS5925 X40CrMoVN16-2 UNS : S42025 Euro Number: 1.4123 Boeing: BMS 7-357 ASTM F899 |

Get XD15NW® at Sullivan Steel

XD15NW® (X40CrMoVN16-2; AMS 5925) is currently available at Sullivan Steel in electro-slag remelted (ESR) bar stock from 0.1496" (3.8mm) to 7.992" (202mm). Get in touch with our experts to request a quote or inquire about XD15NW®.

Chemical Composition

| C | Si | Mn | Cr | Mo | V | N | Ni | |

|---|---|---|---|---|---|---|---|---|

| min. | 0.37 | – | – | 15.00 | 1.50 | 0.20 | 0.16 | – |

| max. | 0.45 | 0.60 | 0.60 | 16.50 | 1.90 | 0.40 | 0.25 | 0.30 |

Heat Treatment

HRC of at least 58 after tempering at low (around 180°C/360°F) and high (500°C/932°F) temperatures. Low residual austenite after heat treatment in order to ensure a high dimensional stability of the parts. Heat treatment is relatively simple, utilizing standard equipment.

Comparisons to Other grades

XD15NW® is often used as an improvement over 440C and as an alternative to AMS 5898.

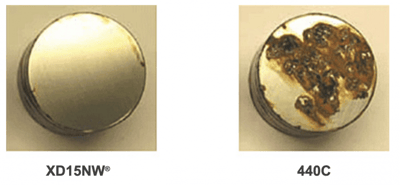

The photo below compares XD15NW® corrosion resistance to 440C (X105CrMo17). While 440C offers great general corrosion resistance, XD15NW® has superior resistance in highly corrosive environments.

Corrosion Resistance Comparison (XD15NW® vs. 440C) – Aspect of the surface after 96 h salt spray (NaCl) exposure. For both grades, heat treatment cycle: 1050 °C Oil/ -75 °C/ 180 °C

This high corrosion resistance makes XD15NW® a viable alternative to AMS 5898 in many critical aerospace applications.

Applications

XD15NW® is most associated with aerospace manufacturing, but it also has applications in medical and food & beverage equipment manufacturing and in cryogenic environments. In the medical industry, for example, XD15NW® is valued as an autoclavable steel grade well-suited for frequent sterilization.

Common components using XD15NW® include:

- Bearings (ball, roller and spherical)

- Ball and roller-screws

- Rod Ends

XD15NW® Resources

- XD15NW® Datasheet

- XD15NW® Brochure

- XD15NW® manufacturing example in detail from Enduro Bearings

- A Comparison of the Mechanical and Physical Properties of Contemporary and New Alloys for Aerospace Bearing Applications

Expert Support & Service for XD15NW®

Sullivan Steel is the exclusive North American distributor for XD15NW®, and our team has extensive experience working with the grade. Have questions before you get started? Request a quote and include your questions, and we’ll get one of our XD15NW® experts in touch with you.