Short Lead Times

Expect fast responses, rapid turnarounds, and on-time delivery.

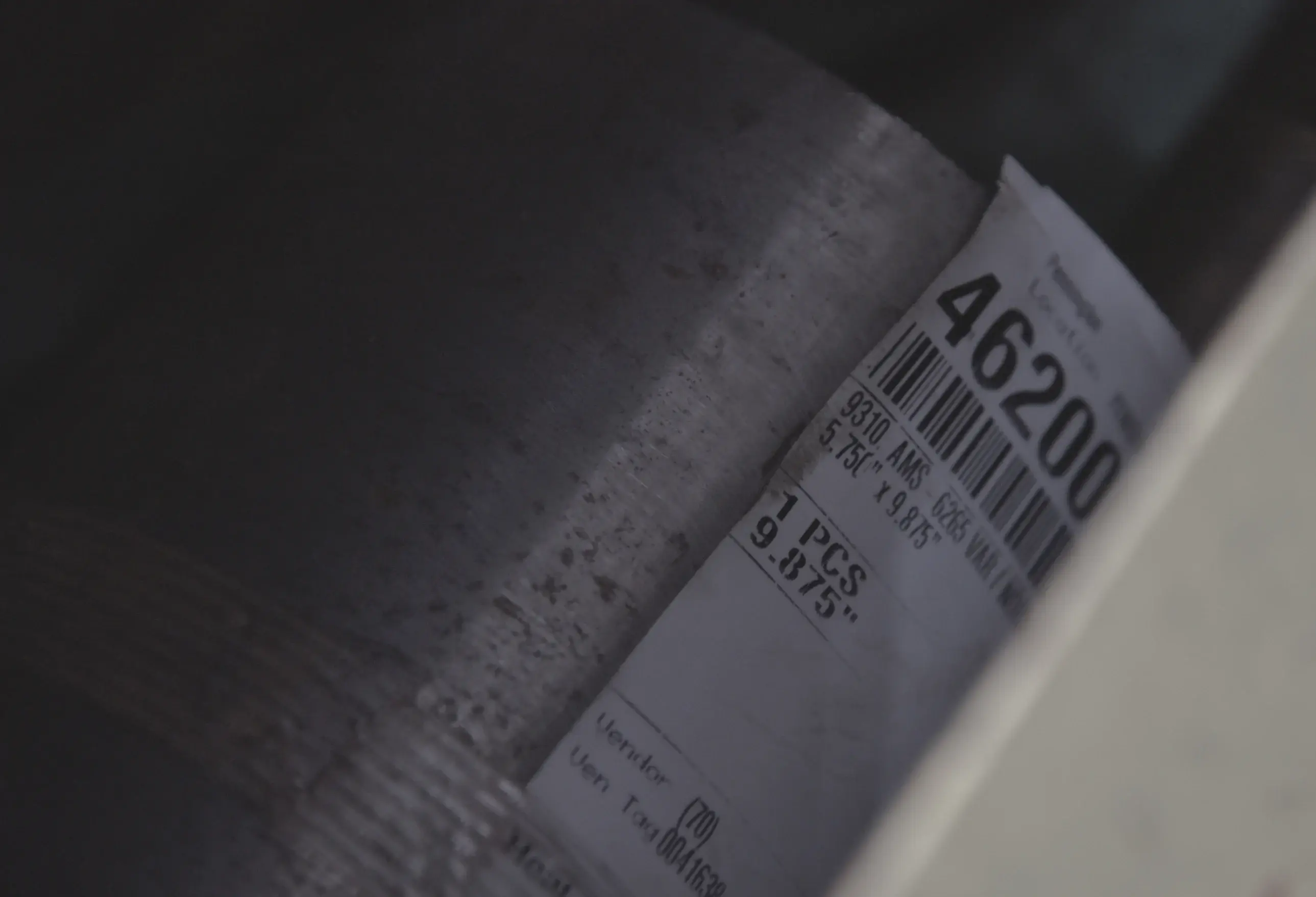

9310 is a premium carburizing bearing and gear steel with high hardenability, high core hardness, and high fatigue strength. In the carburized condition, 9310 achieves excellent wear resistance and a tough core.

| Type | Specifications |

|---|---|

| AMS | AMS 6260, AMS 6265, AMS 6267, AMS 2300, AMS 2301, AMS 2251, AMS 2259 |

| ASTM | ASTM A751 |

| UNS | G93100 |

| EN/DIN | 10NiCrMo13-5, 35NCD16 |

| Form | Size range |

|---|---|

| Bar | 0.4375" - 12.000" |

| Element | Range (%) |

|---|---|

| C | 0.10 |

| Cr | 1.20 |

| Fe | 94.58 |

| Mn | 0.50 |

| Mo | 0.12 |

| Ni | 3.25 |

| Si | 0.25 |

| High temperature | Stainless | Through-hardened | Nitriding | Carburizing | Induction |

|---|---|---|---|---|---|

| Characteristic | Value |

|---|---|

| High temperature | |

| Stainless | |

| Through-hardened | |

| Nitriding | |

| Carburizing | |

| Induction |