52100

52100 is a high-carbon, deep-hardening chromium bearing steel with excellent fatigue strength and wear resistance properties. While suitable for premium aerospace parts, it is also considered an economical alternative to many tool steels or carburizing grades.

STANDARDS

| Type | Specifications |

|---|---|

| AMS | AMS 6440, AMS 6444, AMS 2300, AMS 2301, AMS-STD-2154 |

| ASTM | ASTM A295, ASTM A892, ASTM A519, ASTM A485 |

| UNS | G52986 |

| EN/DIN | 100Cr6 |

| EN | 1.3305, 1.3514 |

| BS | S135 |

SIZES AVAILABLE

| Form | Size range |

|---|---|

| Bar | 0.130" - 15.750" |

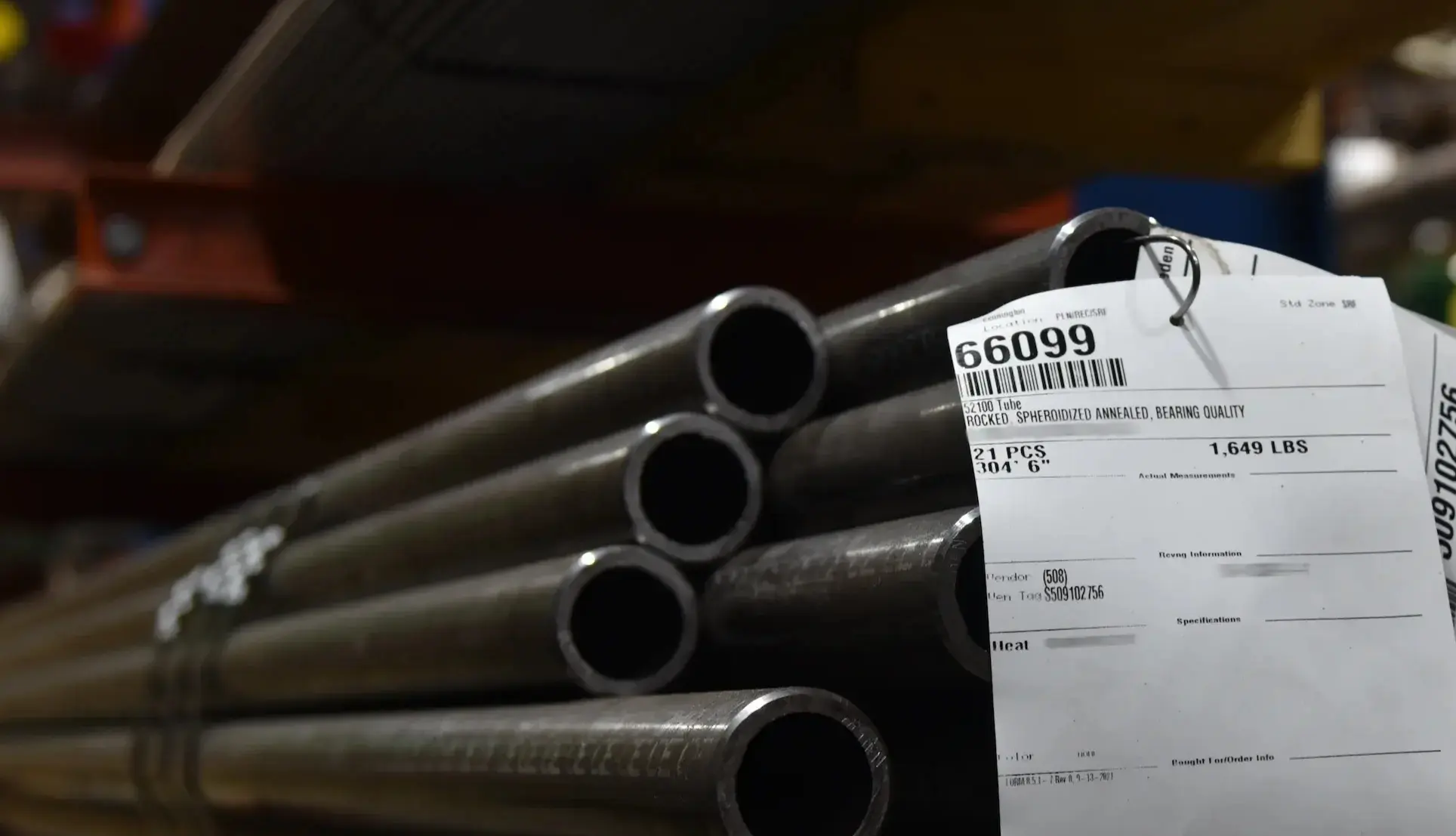

| Tube | 0.777" - 12.404" |

| Wire | 0.114" - 0.3347" |

CHEMICAL COMPOSITION

| Element | Range (%) |

|---|---|

| C | 0.98 - 1.10 |

| Cr | 1.30 - 1.60 |

| Fe | 96.50 - 97.32 |

| Mn | 0.25 - 0.45 |

| P | 0.03 max |

| S | 0.03 max |

| Si | 0.15 - 0.30 |

CHARACTERISTICS

| High temperature | Stainless | Through-hardened | Nitriding | Carburizing | Induction |

|---|---|---|---|---|---|

CHARACTERISTICS

| Characteristic | Value |

|---|---|

| High temperature | |

| Stainless | |

| Through-hardened | |

| Nitriding | |

| Carburizing | |

| Induction |

ADDITIONAL INFO

52100’s VAR and VIM-VAR variants provide added melt quality that improves the cleanliness and internal soundness of the steel relative to its air-melted counterpart. VIM-VAR differs from VAR in the addition of Vacuum-Inducting-Melting prior to the VAR remelt. Modified 52100 may also be available in certain tube diameters, which enables the hardening of thicker cross sections.

Heat treatment instructions and recommendations for 52100 are provided by two of our mills, Carpenter and Ovako. Sullivan Steel’s modified 52100 specified to ASTM A485 Grades 1 and 3 may eliminate the need for water quenching in some cases. Please contact Sullivan Steel for additional guidance or information.

Sullivan Steel typically stocks 52100 in the spheroidized annealed condition, optimal for machinability and heat treatment uniformity. Exceptions may apply. The long spheroidizing anneal may decarburize the exposed surfaces to depths controlled by ASTM A295—this shallow decarburized surface must be removed in machining.

Anti-friction bearings, rollers, knives and cutlery, seals, sleeves, bushings, tools, dies, molds, engines, hydraulic parts, aircraft flaps and slats.