Martensitic Stainless Steels: Achieving High Through Hardening Strength with Corrosion Resistance

Martensitic stainless steels are known for strength, hardness, and corrosion resistance. This blog post delves into the microstructure of these steels and how they are engineered to deliver specific performance characteristics.

The Microstructure of Martensitic Steel

A steel’s “phase” and its associated microstructure plays a huge part in the properties it exhibits, such as hardness and ductility. It’s possible to manipulate the phase of a steel by controlling its composition and thermal or mechanical treatment – heating, cooling, and/or mechanically working the metal. These are used to create the multitude of steel types/grades that exist today. This is especially true for the five primary families of stainless steels: Ferritic, Martensitic, Austenitic, Duplex, and Precipitation Hardening. The first three are named based on the metallurgical phase that provides their matrix microstructure in their applied condition.

As a result, the ferritic grades (ferrite matrix) are relatively soft and ductile, while martensitic grades (martensite matrix) can achieve high hardness/strength. The property values are dependent on the base metallurgical phase along with other microconstituents that are present in the applied condition microstructure, which results from the processing of the steel throughout the creation of a finished part.

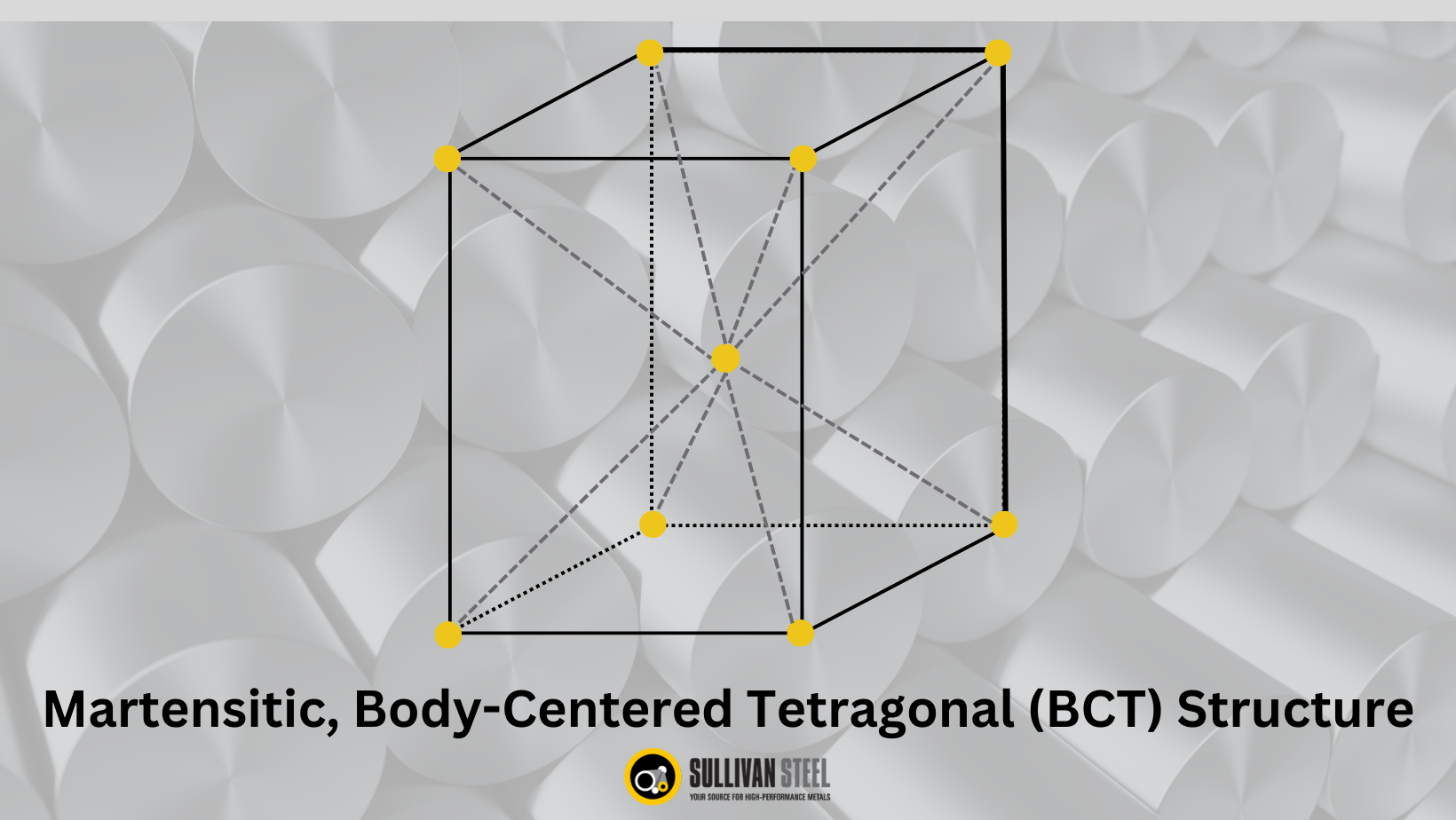

Metals are crystalline in nature. The atoms, for any given phase/microconstituent, are arranged in one of several geometric standard patterns (e.g., cubic, tetragonal, hexagonal, etc.).

A martensitic microstructure is usually created by specific heat treatment followed by quenching (very rapid cooling). The resulting crystal structure is body-centered tetragonal (BCT), where large atoms, such as iron, exist on the corners and in the center of each unit cell; and smaller carbon atoms force themselves between the larger ones on one leg of the lattice. This strained lattice imparts the hardness (strength) properties to martensitic steel.

Enhancing the Performance of Martensitic Steels

A martensitic bearing steel is very hard thanks to its robust crystalline structure, but it tends to be brittle. Luckily, we can amend this and bolster other performance characteristics with thermal treatment and composition. For instance:

- Low Temperature Tempering decreases brittleness yet maintains much of martensite’s hardness.

- Adjusting alloying elements, like adding nitrogen, or adding chromium and molybdenum can enhance corrosion resistance.

It’s important to note that the depth to which a particular grade will fully harden during a given thermal treatment depends on the composition of the steel. Again, adding alloying elements can affect the outcome of heat treatment.

Martensitic Stainless Steel and Non-Stainless Grades

Many steel grades can achieve a martensitic microstructure. Designers may request specific grades to achieve certain characteristics/properties. Here are the most popular.

Non-stainless Grades

- 52100 is a homogeneous high-carbon, chromium alloy usually heat treated to provide a through section hardness of 61/63 HRC in a finished component. Modified grades of 52100 (i.e., ASTM A485-1 and ASTM 485-3) provide greater hardenability. They can achieve a fully hardened martensitic microstructure in thicker cross sections/larger parts.

Stainless Grades

- 440C – Widely used for its high hardness, 440C is a stainless steel with moderate corrosion resistance properties.

- XD15NW® – A high-performance grade containing nitrogen, XD15NW® has superior corrosion resistance compared to 440C. It can also achieve impressive hardness and strength, making it suitable for the most critical components.

- XD16N – An air-melt variant of XD15NW®

Applications for Martensitic Steel

Martensitic steels are well-suited to applications where through hardening is essential:

- Bearings (especially ball bearings)

- Ballscrews

- Gears

- Automotive components (cams and clutches)

- Knives and cutting blades

- Critical aerospace components

A Note on the Terminology: Martensitic Steel

Martensitic steel isn’t just one specific type or grade of steel—it refers of a number of alloy grades with metallurgical capabilities to achieve a martensitic microstructure in parts various sizes, typically achieved through heat treatment and quenching.

The depth to which martensite forms in a given component depends on the steel’s composition and the processing parameters employed. Choosing a suitable grade means matching the steel’s hardenability to the depth of hardness required for a component in conjunction with the capability of the processing equipment being used.

It takes special knowledge to select a martensitic stainless steel. The alloying elements of the steel must be specifically composed to attain the required performance characteristics, such as ( but not limited to) hardness, fatigue strength, corrosion resistance, toughness, or temperature resistance.

Sullivan Stocks High-Performance Martensitic Steel

At Sullivan Steel, we stock specialty metals that include both standard and stainless martensitic steel grades for demanding applications. Our experts are friendly and knowledgeable, ready to recommend suitable grades, and guide you through the processing needs of your application.